Epoxy Resin Systems

Which Epoxy Resin to select

General Art Epoxy Resin: For layers and casting from 1mm up to 10mm thick. A somewhat thicker resin with lower flow. Perfect for casting into shallow silicone moulds where it is important to reduce pigment settling. Ideal for resin art on flat surfaces, encapsulating objects, crack filling and bonding together materials. Not recommended for countertops.

Countertop & Art Coating Epoxy Resin: Has a higher flow (thinner) than General Art Epoxy Resin but a lower flow (thicker) than our Casting Resins. Poured in layers of 1.0 to 1.5mm thickness in countertop applications. Ideal for resin art on flat surfaces, for creating a clear coat over acrylic art and for decoupage art.

Countertop and Shallow Casting Epoxy Resin: This resin has a higher flow and cures even harder than our Countertop Epoxy Resin. The higher flow means that trapped air bubbles are almost never a problem. For jewellery, coasters and other shallow mould castings from 1mm up to 5mm thick. Poured in layers of 1.0 to 1.5mm thickness in countertop applications and can be used for kitchen countertops. Ideal for resin art on flat surfaces and for creating a clear coat over acrylic art. Certified safe for food contact applications.

Countertop and Shallow Casting Epoxy Resin: This resin has a higher flow and cures even harder than our Countertop Epoxy Resin. The higher flow means that trapped air bubbles are almost never a problem. For jewellery, coasters and other shallow mould castings from 1mm up to 5mm thick. Poured in layers of 1.0 to 1.5mm thickness in countertop applications and can be used for kitchen countertops. Ideal for resin art on flat surfaces and for creating a clear coat over acrylic art. Certified safe for food contact applications.

Medium Casting Epoxy Resin: Moulds and river tables which require casting in layers from 5mm up to 20mm thick. Certified safe for food contact applications.

Deep Casting Epoxy Resin: Moulds and river tables which require casting in layers from 20mm to 80m thick (even 100mm in cool weather).

UV Cured Resin: For small resin applications up to 3mm thick, such as jewellery, where a very fast cure is required. Use as clear or with only light colouring.

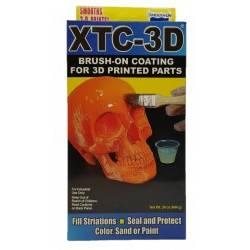

XTC-3D Brush-On Coating: Brush onto 3D printed objects, resin castings and many other surfaces to create a smooth, glossy finish.

You can start out with one of our Starter Packs. They contain all you need to gain experience with resin, colour and resin effects.

-

View

Details

General Art Epoxy Resin

from R 263.00 -

View

Details

Countertop & Art Coating Epoxy Resin

from R 476.00 -

View

Details

Countertop & Shallow Casting Epoxy Resin

from R 578.00 -

View

Details

Medium Casting Epoxy Resin

from R 578.00 -

View

Details

Deep Casting Epoxy Resin

from R 506.00 -

View

Details

UV Cured Resin: 200g

R 438.00 -

View

Details

Resin Release Wax: 400ml

R 179.00 -

View

Details

Liquid Wax Release Agent for Moulds: 30ml

R 53.00 -

View

Details

XTC-3D Brush-On Coating

from R 374.00 -

View

Details

Epoxy Resin Starter Packs

from R 1,232.00